View: Time: 2017-12-21 23:52:46

Why tempered glass is there a explode rate?

spontaneous detonation is not affected by external visual impact of their split a piece of glass pattern, and even their own Suidiao situation. There are generally two kinds of triggering situations. The nickel sulfide is the main reason of the production process, will be mixed with impurities such as nickel sulfide (NiS) crystal stuff, when make it into a crystal form, and the beta crystal at room temperature is more stable, so the daily use by alpha into beta crystals, the beta crystalline volume ratio 2 - alpha 4%, Many a little make a mickle. serious unbalanced stress, internal, and burst. Similar to the case of bimetallic heating, due to the difference of the expansion coefficient and the overall thermal expansion coefficient of some other discordant small Dongdong, some of them expanded after heating, some of which did not react, so they split.

I. Tempered glass explode, and its classification

1, the classification of tempered glass tempered glass explode birth, accompanied by self ask. Tempered glass explode can be expressed as a tempered glass without external directly under the action of automatic broken phenomenon. Can occur in the tempered glass explode in tempering processing, storage and transportation, installation and use of the process. According to the different causes of suicide can be divided into two kinds: one is caused by defects in the visible glass explode, such as stone, sand, bubbles, inclusions, gap, scratch, edge; two is made of nickel sulfide in glass (NIS) impurities and heterogeneous particles caused by tempered glass explode. 2, the controllable characteristics of tempered glass tempered glass explode reason unclear explosion problem, the responsibility is difficult to understand. Self time no uncertainty, may be just released, may also be manufactured from 1 to February, there are 1 to 2 years before the factory explosion, causing more tempered glass blew time may be the production after the completion of the 4 ~ 5 years. It is not fully understood, the probability of most manufacturers products is around 3 of the explosive rate; the probability of individual manufacturers of products may be even higher. The fundamental reason is because the glass blew glass containing nickel sulfide and heterogeneous particle impurities, impurity is how to mix? It is not yet clear how glass is mixed into nickel. The most probable source is all kinds of nickel alloy parts used on equipment and various heat-resistant alloys used in furnaces. For the oil burning furnace, it was reported that the condensate rich in nickel was found in a small furnace. Sulfur is unquestionably derived from the sulfur content in the mixture and in the fuel. When the temperature is over 1000 C, nickel sulfide exists in molten glass in the form of droplets, and the curing temperature of these small droplets is 797. 1 grams of nickel sulfide can produce about 1000 small stones with a diameter of 0.15mm. Nickel sulfide can occur at any time after the production is completed, so it can not be completely eliminated. There has been no effective way to prevent it from being called "cancer of glass curtain wall". "Cancer of the glass curtain wall" is from the mouth of the famous architect Forster. In that year, the London City Hall block was broken from floor to ceiling height. The town hall near the Tower Bridge of London, all made of glass cladding, the contractor will have to check all the internal glass. A spokesman for the London Metropolitan Council said that according to the preliminary investigation, the problem is that the glass contains nickel sulfide. That is to say, during the construction process, the glass is polluted by nickel and the sulfide in nickel and glass react with it, causing the rupture. The nickel sulfide class blew after the replacement is difficult, high cost, and will be accompanied by high quality complaints and economic losses caused by other owners dissatisfied with even more serious consequences. It is called "cancer of the glass curtain wall".

II. Tempered glass explode rate and explode reason

1, the explosive rate Chinese blew the rate of the manufacturers are not the same, from 3% to 0.3%. The general rate is according to the number of explosive units, without considering the monolithic glass size and the thickness of the glass, it is not accurate enough, can not be compared with each other more scientific. For calculation of the explosive rate, must determine the unified hypothesis. A unified condition: every 5 ~ 8 tons of glass containing enough to trigger a nickel sulfide blew; each piece of toughened glass area average 1.8mm; uniform distribution of nickel sulfide. The calculated 6mm thick tempered glass explode calculation rate is 0.64% ~ 0.54%, 6mm toughened glass of the explosive rate is about 3 per thousand to 5 per thousand. This is in accordance with the actual value of the domestic high level processing enterprises. Even completely according to the standard production, can not completely avoid the tempered glass explode. Large buildings easily using hundreds of tons of glass, which means that the heterogeneity of nickel sulfide and impurity rate in glass, toughened glass is by the hot dip process, explosion is inevitable.

2, toughened glass blew uncontrollable reasons - nickel sulfide (NiS) sources and heterogeneous phase particles toughened glass is not controllable spontaneous is not only NIS particles in traditional ideas, there are many other heterogeneous particles. The crack germination and expansion in glass is mainly due to the residual stress in the vicinity of the particles. This kind of stress can be divided into two kinds, one is the phase change stress in the process of phase change expansion and the other is the residual stress caused by the mismatch of the thermal expansion coefficient. Nickel sulfide (NIS) and heterophase particles. The interior of the glass containing nickel sulfide impurities exist in the crystal state, in general, will not cause the broken glass, but because of the toughened glass reheating, changed the phase state of nickel sulfide nickel sulfide impurities, high temperature alpha state in glass quenching is frozen, they return to beta state could take years since the nickel sulfide impurities at low temperature, will produce beta state volume increases, local stress concentration in the internal glass, tempered glass explode when will happen. However, only relatively large impurities will cause to explode, and only when the impurity can occur in the core parts of the tempered glass explode when tensile stress. NIS is a kind of crystal. There are two kinds of crystalline phases: high temperature phase alpha -nis and low temperature phase beta -nis. The phase transition temperature is 379 degrees. When the glass is heated in the toughening furnace, the NIS is all transformed into the alpha phase because the heating temperature is much higher than the transformation temperature. However, during the subsequent quenching process, the alpha -nis was not converted to beta -nis, which was frozen in the tempered glass. At room temperature, the alpha -nis is unstable and has a tendency to gradually change to beta -nis. This transition is accompanied by about 2 to 4% of the volume expansion of the glass transition under tensile stress is huge, as a result of suicide. SEM images extracted from glass fragments in NIS after explosive stones can be seen, the surface is very rough and bumpy. The heterogeneity of particles caused by tempered glass explode, can see the photos at the cross section of rupture source of broken glass, caused by a spherical particle first crack boundary region and the two signs of fragmentation.

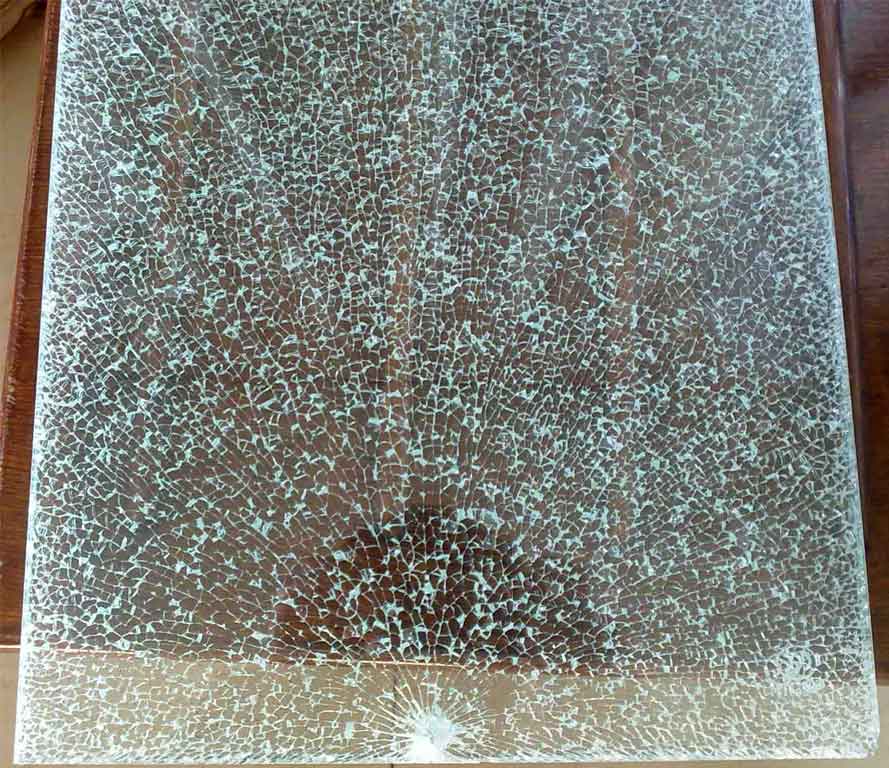

3, how to identify the first self tempered glass (tempered glass crack initiation point radially, both the starting point in the middle of the glass) whether, as in the edge of the glass, usually because of the glass without chamfering processing or glass edge damage caused by stress concentration, the crack gradually caused; such as initiation in the middle of glass, to see whether there is a similar initiation point two butterfly wings pattern consisting of two small polygons (such as careful observation, hudieban) two small polygon public side (butterfly body) should be visible to the naked eye black small particles (nickel sulfide stones), can judge is spontaneous; otherwise it should be the external damage. The typical characteristics of glass explode is hudieban. Pieces of glass radial distribution, radiation center has two block like butterfly wings of glass block, commonly known as "butterfly". NIS calculi in two "Butterfly" interface. To investigate the radial stress r a tangential stress of interface between R or a particles and glass for heterogeneous particles in the glass matrix

4, tempered glass explode mechanism theory, the cooling process temperature is negative, so the radial particles around the stress pressure, tangential stress is tensile. The scanning electron microscope image and the edge extrusion morphology of the spherical silicon particles in the middle layer of the glass are the radial stress of the surrounding particles and the tangential stress is the tensile force. So the tangential stress is the root of the crack initiation.

. Structural Glass Curtain Walls

. What is color! Simple Talking ...

. Advantages and uses of toughen...

. Various glass defects and solu...

Office Addr:Room 1107, B1 Block, Tianan Cyber,Nancheng Area, Dongguan City, Guangdong Province, China,

Factory Addr:Taiying Industrial, Hongmei Town, Dongguan City, Guangdong Province, China

86-769-22273585

86-18145870793

![]()