View: Time: 2017-12-20 23:38:54

Common problems in the inspection of insulating glass and the choice of materials

China's production of insulating glass began in the 1960s. After nearly 50 years of development, especially in the past decade or so, the technical level and quality of hollow glass in China have greatly increased. With the improvement of national energy-saving requirements and people's awareness of energy conservation, people are gradually realizing that the life of hollow glass is crucial to the energy saving of insulating glass. Insufficient sealing of insulating glass can not only save energy, but also result in energy waste.

The company is located in:

The revision of the national standard of insulating glass is to promote the technical progress and product quality of the insulating glass industry. In the new national standard for insulating glass, the "service life" is first proposed: the quality of various materials for making insulating glass is closely related to the service life of insulating glass, and the service life of insulating glass produced by using materials conforming to the standards and standards is generally not less than that In 15 years [1]. This hollow glass materials and processing and manufacturing control put forward higher requirements. In this paper, from the point of view of testing laboratories, the common problems commonly encountered in the market of double-sealed airtight glass and their influence on the hollow system are emphatically elaborated.

The company is located in:

First, the insulating glass common problems

The company is located in:

With the development of science and technology and the research of scientific researchers, a great deal of scientific and technological achievements have been widely applied to the production of hollow glass and its materials. The quality of hollow glass in China has been greatly improved. However, we can not ignore the quality problems of insulating glass. Judging from the results of laboratory tests and social reactions, there are still many problems with their quality. These problems are mainly reflected in the following aspects:

The company is located in:

① early failure of hollow glass: the performance of hollow glass, dew condensation, butyl plastic solution flow, short life;

The company is located in:

② butyl rubber gum, varying width, and some parts of the glass from the channel;

The company is located in:

③ the inner rubber and plastic outside the gas lines between the outside;

The company is located in:

④ outside the rubber deep does not meet the requirements;

The company is located in:

⑤ mixing A: B component ratio deviation is too large, caused by uneven mixing of incompatible, non-bonded phenomenon;

The company is located in:

⑥ molecular sieve filling storage time is too long, resulting in molecular sieve failure and so on.

Second, the requirements of hollow glass materials

The company is located in:

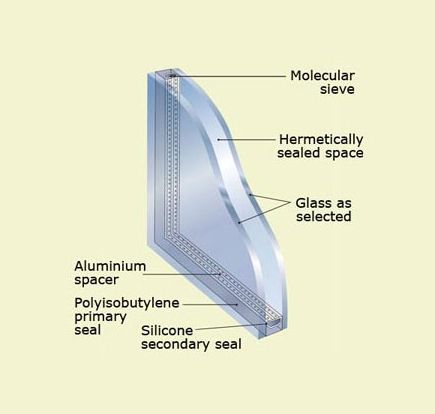

In the insulating glass member, the sealant, the desiccant, the spacer and the glass form an insulating glass seal system. The quality of the edge seal system determines the service life of the insulating glass.

The company is located in:

1, sealant

The company is located in:

In addition to glass, sealant as the key material of hollow glass edge sealing system, its bonding with glass, its own moisture permeability, elastic modulus, elastic recovery rate and other properties directly affect the service life of insulating glass.

The company is located in:

Insulating glass sealant, the water vapor permeability performance (value), butyl sealant The company is located in: In addition to having good aging properties, the insulating glass outer wall sealant also provides protection for the inner sealant, butyl rubber, as well as high modulus of elasticity and elastic recovery rate as well as good adhesion to ensure that the edge Good seal, sufficient resistance to tensile and shear strength to withstand all the static and dynamic loads borne by the insulating glass. The company is located in: 2, desiccant The company is located in: Due to the desiccant spontaneity of water adsorption, in order to ensure the long-term use of insulating glass, it requires high static water adsorption capacity and low adsorption rate. During the production process, it takes time for the desiccant to fill the laminate due to process limitations, during which time the desiccant spontaneously adsorbs the moisture in the air. The low adsorption rate ensures that during this process, the desiccant adsorbs less water and maintains a higher residual adsorption capacity. High static water adsorption capacity to ensure that the desiccant sealed in the hollow cavity of the water vapor and the use of the sealant to penetrate into the hollow cavity during the adsorption of moisture to maintain long-term cavity cavity dry. Changes in temperature will cause changes in the stress in the hollow cavity, resulting in the deflection of the glass. The desiccant on the air adsorption or desorption of aggravated the role of such flexural deformation. 13X zeolite has the strongest air adsorption / desorption capacity during the drop / temperature increase, followed by 4A molecular sieve, and 3A molecular sieve has almost no adsorption capacity on air. 3A molecular sieve has become the preferred material for insulating glass desiccant. The company is located in: 3, spacer The company is located in: In addition to providing desiccant storage space, the spacer as a rigid frame, its role is to effectively isolate the glass to form a hollow cavity to support and improve the sealant sealing capacity, improve the performance of insulating glass. Common spacers are metal spacers, composite tapes, hybrid spacers and super spacers. The company is located in: Metallic spacers, especially aluminum and stainless steel spacers, have similar coefficients of thermal expansion to those of glass under well-defined conditions. The expansion and contraction of spacers are consistent with that of glass, reducing the sealing stress. Although the thermal expansion coefficient [23.6cm / (cm · ° C) × 10-6] of the aluminum spacer is larger than the thermal expansion coefficient [15.7cm / (cm · ° C) × 10-6] of the stainless steel spacer, Light, relatively inexpensive and relatively easy to produce, bend, aluminum spacers should be more widely available in the market. The company is located in: In view of its role, the spacer should ensure that the desiccant in the spacer can smoothly adsorb the moisture in the hollow cavity under the condition of ensuring good rigidity. The company is located in: Third, the impact of materials on the insulating glass In the factors that affect the quality of hollow glass, hollow glass is undoubtedly the most critical factor. However, sealant bonding performance is poor, elastic recovery rate is low, the desiccant residual adsorption capacity is poor, the poor permeability of the spacer abound, eventually leading to failure of insulating glass seal early. The company is located in: Such as sealant. Contaminants in the outer sealant or environment can invade the butyl gum by direct or indirect migration due to impurities in the composition or the presence of contaminants in the environment of use of the assembly (such as low molecular weight mineral oil), causing the butyl gum to dissolve and swell , "Tears" phenomenon [2], thus affecting the service life of insulating glass. The company is located in: Such as 3A molecular sieve. Due to unacceptable quality of 3A molecular sieve (K / Na ion exchange rate is too low), or other types of desiccant mixed with 3A molecular sieve and even used as 3A molecular sieve, it increases the adsorption capacity of desiccant to the air in the hollow system, Moisture adsorption; in the process of thermal expansion and contraction, exacerbated the deformation of the edge of the sealant, increasing the infiltration of water vapor channels, making it easier for water vapor from the outside world to penetrate into the hollow cavity, resulting in desiccant on the water vapor Absorption of the burden, thus affecting the service life of insulating glass. Such as aluminum spacers. Due to poor aeration, the molecular sieve in the spacer can not directly contact with the moisture infiltrated into the hollow cavity, which can not be easily absorbed by the water vapor, resulting in the accumulation of more water and vapor in the hollow cavity. The company is located in: In the 2012 edition of the IG standards, in order to more fully examine the durability of the IG system, the durability of high temperature and humidity and the durability of the weather cycle before the water vapor sealing durability were replaced. During the test, the deformation and displacement of the sealant are maximized, thereby accelerating the infiltration of moisture and further testing the performance of the edge material. Therefore, the selection of high quality materials is the premise and basis for the production of high quality insulating glass.

. Structural Glass Curtain Walls

. What is color! Simple Talking ...

. Advantages and uses of toughen...

. Various glass defects and solu...

Office Addr:Room 1107, B1 Block, Tianan Cyber,Nancheng Area, Dongguan City, Guangdong Province, China,

Factory Addr:Taiying Industrial, Hongmei Town, Dongguan City, Guangdong Province, China

86-769-22273585

86-18145870793

![]()